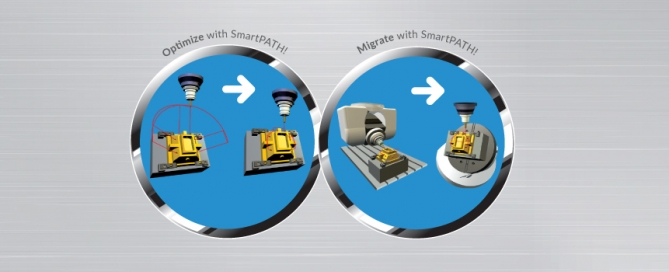

Optimizing composite trimming with Adaptive Post-Processing

Based in Western Cape, South Africa, AAT Composites began producing composite parts for local aerospace and defense industries in 1983, before expanding its offerings into international markets like aviation, marine, automotive, and signage. Now owned by RECARO Aviation Seating, they've established themselves as a market leader in the manufacture and design of innovative composite parts for the high-end automotive and aviation industries. We sat down with [...]