How to generate post-processor commands in CATIA

CATIA uses a PPTable to create the aptsource file that is subsequently used as input to your post-processor. This PPTable defines post-processor commands for typical functions such as tool changes, speeds and feeds, coolant, canned cycles, and so on.

Occasionally though, you may need to enter a post-processor command to produce special output or to get the post-processor or CNC machine to behave differently. CATIA’s Auxiliary Operations dialog allows you to enter post-processor commands that will be included inside the aptsource file.

Post-processor commands must follow the ISO 4343 apt-like standard, which defines strangely abbreviated command keywords (e.g., SPINDL, COOLNT) that are optionally followed by a forward-slash “/” character and parameter list containing numbers and/or more keywords. A complete list of available post-processor commands can be found inside ICAM’s CAM-POST User Guide.

Follow these steps to insert one or more post-processor commands into your manufacturing process:

- 1. First select a manufacturing operation in the PPR tree. The post-processor command(s) will be added after the selected element in the manufacturing process.

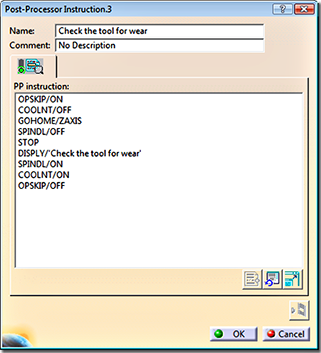

2. Next, select the Post-Processor Instruction button ![]() in the Auxiliary Operations toolbar. The Post-Processor Instruction dialog box will appear allowing you to enter one or more PP instructions (i.e., post-processor commands) as shown in the image below.

in the Auxiliary Operations toolbar. The Post-Processor Instruction dialog box will appear allowing you to enter one or more PP instructions (i.e., post-processor commands) as shown in the image below.

- 3. You can optionally give a more meaningful name to the instruction(s) so that you recognize what they do when later viewed in the PPR tree.

In the example above you can see a typical series of post-processor commands that could be used to optionally halt the machine so that the CNC operator can visually check the tool for unacceptable wear.

If you have a CAM-POST Developer’s license and you find yourself constantly inserting the same group of commands into your NC programs, you should consider creating a post-processor macro to do the same. A CHECK/TOOL macro could easily be written to handle tool checking as shown above. Going one step further, a CHECK/TOOL macro could be added to all of your post-processors, to handle the unique tool checking requirements of each CNC machine.

Benefit to User

The ability to add post-processor commands to the CAM manufacturing process allows one to take full advantage of the post-processor and CNC machine.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@fr.icam.com